spray drying temperature

Moisture control is crucial to spray drying. Thin coats of spray paint on metal can be dry to the touch after only 10 minutes.

Spray Drying Taking The Heat Out Of Processing Sensitive Products

Sep 25 2003.

. If the outlet temperature of the second stage drying and the temperature of the drying chamber is low the. Two-stage drying involves spray drying to a moisture content which is for normal milk powders about 2 - 5 higher than the required final moisture content. What is the optimal outlet temperature.

Partly because of the high surface tension of water. Without considering the high energy consumption spray drying is the most commonly used method because this process reduces the thermal effect on the powder product. In the chamber atomized liquid is brought into contact with hot gas usually air at a vacuum resulting in the evaporation of 95 of the water contained in the droplets in a matter of a few seconds.

Hello Ben You must decrease the time leg to improve your spray drying process. Whether you are interested in a fluctuating dynamic process temperature dependency or an ageing related study we have decades of expertise across a wide range of industries suited to solving technical challenges. Optimizing a spray dryers capacity is to increase T by raising the inlet tempera-ture or lowering the outlet temperature.

The outlet temperature from the spray dryer is about 15 - 25C lower than with a single-stage process. The slurry is then fed into a spray drier usually a tower heated to temperatures above the boiling point of water. According to the numerical optimization optimum feed soluble solid content inlet and outlet air temperatures were 15 Bx 160 C and 67 C respectively with a desirability factor of 0822.

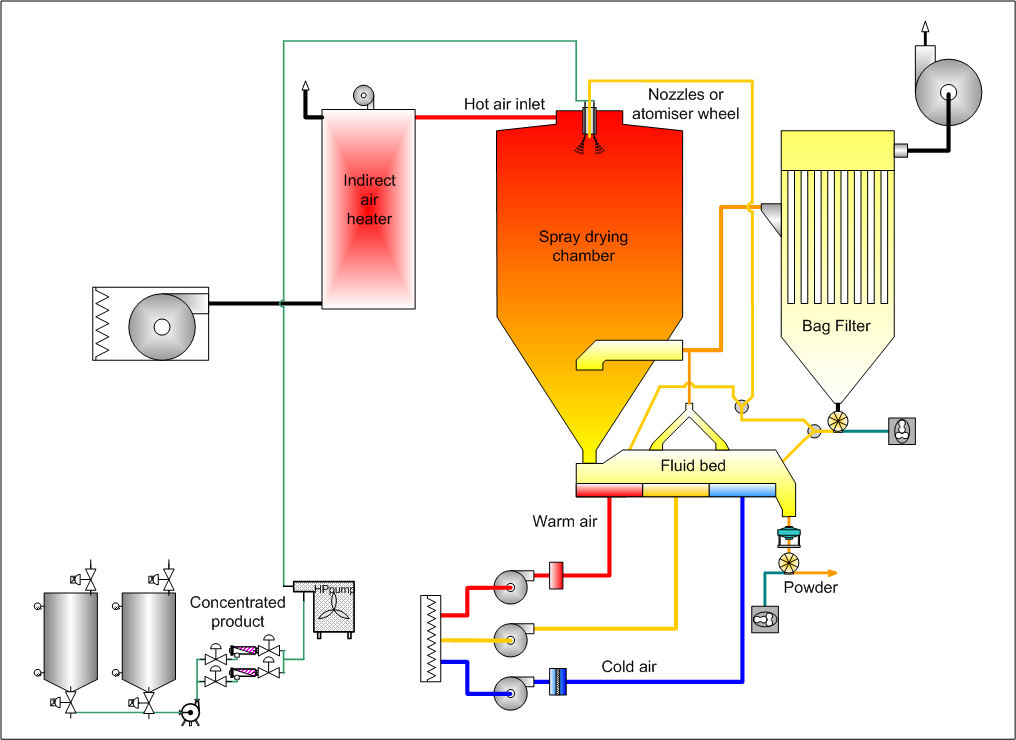

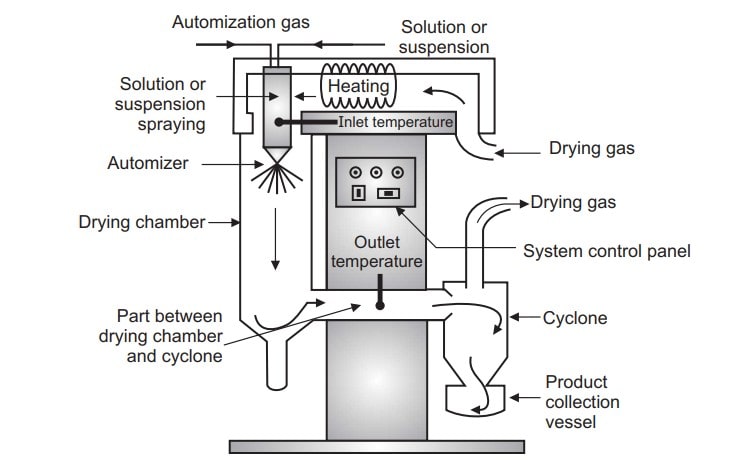

Subsequent fluid bed drying then removes the excess of moisture. Spray drying is the continuous transformation of feed from a fluid state into dried particulate form by spraying the feed into a hot drying medium. Drying kinetics of the spray-drying process comprise several steps with different durations and specific events as shown in Figure 5 2 12.

The outlet temperature is a manifestation of the relative humidity in the outlet air. Because it has a lower risk of damage from high temperatures and also because its more flexible co-current drying is the most widely used type of spray drying. From Routine Spray Drying Analyses to Sophisticated Characterisation of Rheology and Surface Tension.

Spray drying of milk is widely known by people in dairy industry. The feed may be. If the outlet temperature is too low the product particles in the drying chamber.

A substance to be encapsulated the load and an amphipathic carrier usually some sort of modified starch are homogenized as a suspension in water the slurry. Temperature evolution during drying kinetics of a sprayed liquid droplet. Of course other parameters like solid feed flowrate water content air supply flowrate etc should.

The drying temperature and drying time need close monitoring due to varying levels of humidity present in the inlet air. Spray drying often is used as an encapsulation technique by the food and other industries. Spray drying often is used as a method of encapsulation.

The spray drying process involves the atomization of a solution slurry or emulsion containing one or more components of the desired product into droplets by spraying followed by the rapid evaporation of the sprayed droplets into solid powder by hot air at a certain temperature and pressure. Paint dry time for metal is typically lower than for other materials. However it can take up to 24 hours.

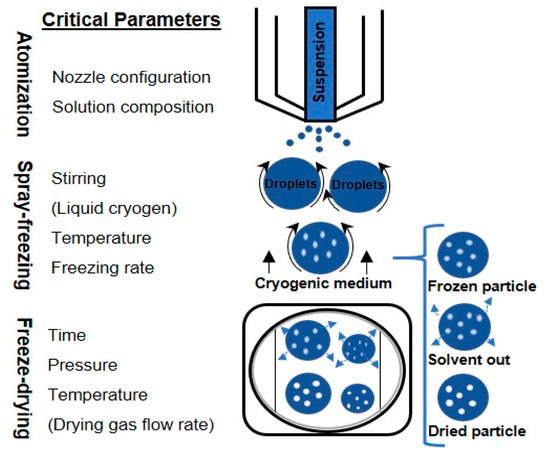

Spray drying might potentially cause particle aggregation due to high temperatures shear forces and partial melting of the particles. Freitas and Müller 1998b recommend the use of lipids with melting points 70C eg tribehenin 72C for spray drying. The way in which the spray makes contact with the air in the dryer influences the behavior of the droplet during the drying phase.

As the slurry enters the tower it is atomized. Spray dryers are controlled by programmable logic controllers PLCs or solid-state controllers. In spray drying systems the exhaust air temperature or humidity provides an input signal that by way of a setpoint will modulate the energy supplied to the process.

The spray drying parameters were optimized by considering saponin content and foam volume by response surface methodology. You could control the air temperature in the heat exchanger before feeding to the spay dryer then only monitor the temperature in the spray dryer. Countercurrent spray drying is typically only used for coarse substances that are thermally stable and require high temperatures for drying.

Mechanically these dryers are relatively low maintenance units.

What Is Spray Drying Frontiers In Spray Drying

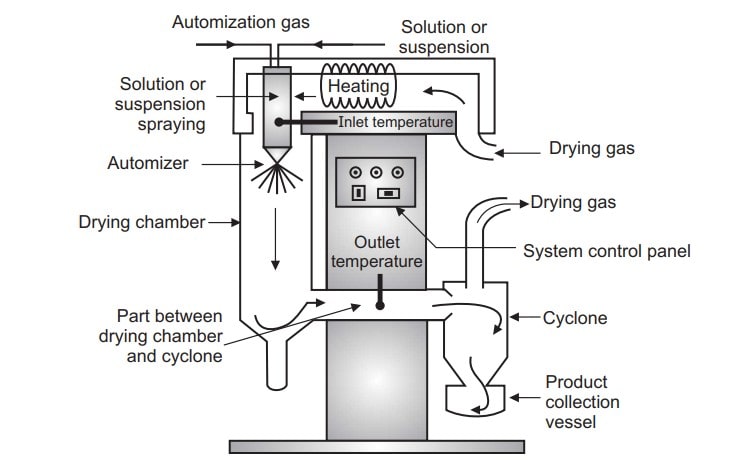

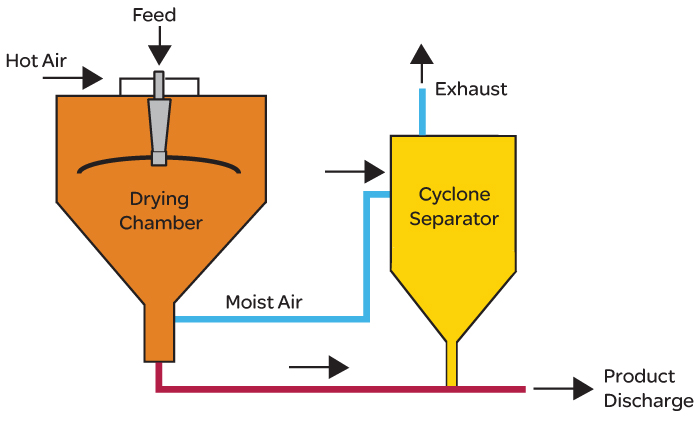

Schematic Diagram Of Spray Dryer 14 Download Scientific Diagram

What Is Spray Drying Frontiers In Spray Drying

Spray Dryer An Overview Sciencedirect Topics

The Spray Drying Process Eurotherm By Schneider Electric

Spray Drying Moisture Challenges Industry Applications Bry Air

The Schematic Diagram Of The Lab Scale Spray Dryer Download Scientific Diagram

Spray Drying Basics Spray Drying Nozzles

5 10 Psychrometric Charts And Spray Drying Project1 1 0 Documentation

Effect Of Spray Drying Temperature On Physicochemical Antioxidant And Antimicrobial Properties Of Pectin Sodium Alginate Microencapsulated Carvacrol Sciencedirect

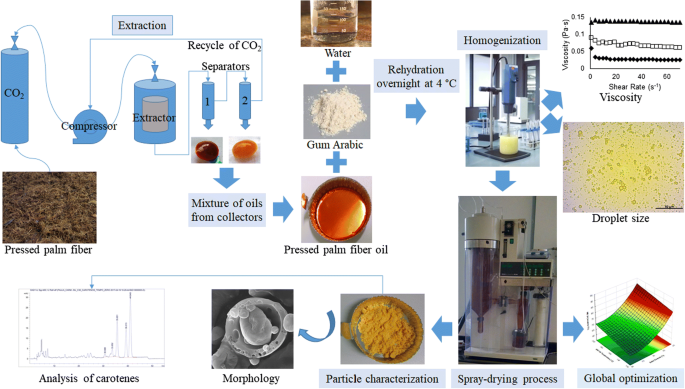

Schematic Diagram Of A Spray Dry Encapsulation Process And Image Of A Download Scientific Diagram

37 Questions With Answers In Spray Dryer Science Topic

Effect Of Solids Content And Spray Drying Operating Conditions On The Carotenoids Microencapsulation From Pressed Palm Fiber Oil Extracted With Supercritical Co2 Springerlink

Spray Dryer Principle Construction Working Pharmacy Gyan

Spray Dryer An Overview Sciencedirect Topics

Schematic Illustration Of Spray Dryer Process And Its Equipment Download Scientific Diagram

Processes Free Full Text Spray Freeze Drying As A Solution To Continuous Manufacturing Of Pharmaceutical Products In Bulk Html

Comments

Post a Comment